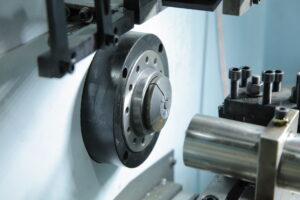

In the field of precision manufacturing, machining small components often presents two major challenges: limited space and complex processes. Traditional large-scale machine tools are not flexible enough to accommodate miniature workpieces, while multi-process operations require frequent machine changes, resulting in inefficiency. CNC Miniature Machine Tools overcome these obstacles with their compact design, multi-functional integration, and high-precision control, setting a new standard for small parts machining. These machines offer a one-stop solution for industries such as electronics, medical devices, and watches.

Space Optimization and Flexibility

✔ Compact Footprint: With a footprint of less than 1㎡ (only 1/3 the size of traditional machines), it can be easily deployed in laboratories, small workshops, or even on a desktop, solving space constraints.

✔ Modular Structure: The machine is designed for quick assembly and disassembly, allowing for seamless integration into production lines or standalone operations.

Expert in Small Parts Machining

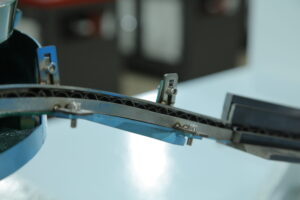

✔ Precision: Capable of machining parts with a minimum diameter of Φ0.5mm, maintaining an accuracy of ±0.005mm, ideal for watch gears, medical probes, electronic connectors, and other ultra-precision components.

✔ Vacuum Clamping and Miniature Tooling: Prevents workpiece displacement or damage, ensuring reliable and accurate processing.

Multi-Functionality and Seamless Process Integration

✔ Four-in-One Functionality: Integrated turning, chamfering, drilling, and tapping functions allow for automatic process switching via pre-programmed settings, reducing 90% machine changeover time.

✔ Optional Fourth Axis: For complex surface machining such as miniature impellers and custom shapes.

Industry Applications & Customer Success Stories

Electronics Industry

📌 Application: Machining miniature RF connectors for 5G communication.

📌 Results: Customer increased product yield from 88% to 99.5%, ensuring higher quality and reliability.

Medical Devices

📌 Application: Precision drilling of disposable surgical handles.

📌 Results: 300% improvement in efficiency, with no burrs left on the workpieces.

Research Institutions

📌 Application: Custom experimental device manufacturing.

📌 Results: Reduced R&D cycles by 50%, speeding up project timelines and innovation.

CNC Miniature Machine Tools

Cost Revolution: Small investment, high return

- Price is only 1/5 of a large machine, and the payback period is reduced to 3-6 months.

- Power consumption is reduced by 70%, and maintenance costs are reduced by 50%.

Technological Disruption: Five breakthroughs in micro-processing

- Nano-scale resolution ball screw, repeat positioning accuracy ≤1μm.

- Intelligent temperature control system, eliminating the influence of thermal deformation on micro-processing.

- 20000 rpm high-speed spindle, surface roughness Ra0.4μm.

Flexible Production: A small-batch customization tool

- 30-second processing program switching, suitable for scientific research, trial production, and personalized orders.