What Factors Affect Chamfering Machine Performance?

A poorly chosen chamfering machine can slow down production, cause material waste, and even lead to costly repairs. I learned this the hard way when I first picked a machine based only on price.

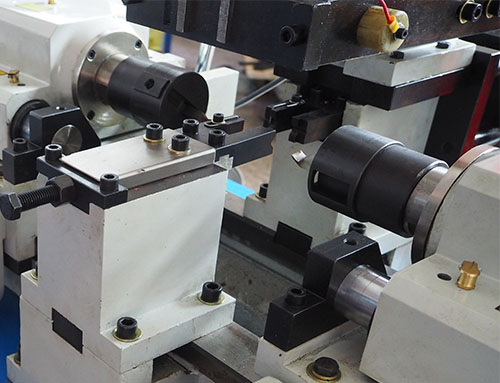

The main factors affecting chamfering machine performance include motor power, blade quality, feed rate, and machine stability. Choosing the right combination ensures smooth, accurate, and consistent chamfering results.

Key Performance Factors Explained

Understanding these factors helps in choosing a machine that meets your needs without overpaying.

Factor |

Description |

Impact on Performance |

Motor Power |

Determines cutting strength | Higher power handles tougher materials |

Blade Quality |

Affects precision and durability | High-quality blades last longer and provide cleaner cuts |

Feed Rate |

Speed at which material moves | Adjustable feed rate allows for different chamfering needs |

Machine Stability |

Reduces vibrations and misalignment | Stable machines provide accurate and consistent results |

By evaluating these aspects, you can avoid machines that struggle with hard materials or produce uneven edges.

Which Chamfering Machine Types Suit Your Needs?

Different chamfering machines serve different purposes. A hobbyist and an industrial manufacturer won’t need the same type of equipment.

Chamfering machines are categorized into manual, semi-automatic, and fully automatic models, each serving different production scales and precision levels. Choosing the right type depends on your workload and required accuracy.

Choosing the Right Machine Type

Let’s compare the main types of chamfering machines to see which one fits your needs best.

Machine Type |

Best for |

Pros |

Cons |

Manual |

Small workshops, DIY users | Low cost, easy to use | Slower, requires manual effort |

Semi-Automatic |

Medium-scale operations | Balance of speed and control | Higher cost than manual |

Fully Automatic |

Large-scale industries | High precision, fast production | Expensive, complex setup |

If you run a high-volume production line, an automatic model saves time and increases accuracy. However, a manual or semi-automatic machine is ideal for occasional use or small-scale work.

How Do Material Types Influence Chamfering Machine Selection?

Not all chamfering machines work well with every material. I once tried using a machine designed for soft metals on hardened steel—big mistake!

The material type determines the required cutting power, blade durability, and machine specifications. Using the wrong machine can lead to excessive tool wear or poor-quality edges.

Matching Material Types to Machine Capabilities

Selecting a machine designed for your specific materials ensures efficiency and longevity.

Material Type |

Best Chamfering Machine Type |

Special Considerations |

|---|---|---|

Aluminum |

Manual or semi-automatic | Requires sharp blades for clean cuts |

Steel |

High-power automatic machines | Needs strong, durable cutting tools |

Plastics |

Manual or semi-automatic | Lower cutting speed to prevent melting |

Wood |

Specialized chamfering machines | Different blade designs required |

Matching your material with the right machine ensures smooth, precise chamfers and extends the machine’s lifespan.

What Safety Features Should You Look for in Chamfering Machines?

Ignoring safety features can lead to accidents, injuries, or machine damage. I always double-check safety settings before operating a new machine.

Key safety features in chamfering machines include emergency stop buttons, protective shields, anti-vibration designs, and automatic overload protection. These features prevent injuries and ensure smooth operation.

Essential Safety Features

A safe chamfering machine protects both the operator and the workpiece.

Safety Feature |

Function |

Why It Matters |

|---|---|---|

Emergency Stop Button |

Instantly stops the machine | Prevents accidents and injuries |

Protective Shields |

Covers moving parts | Reduces risk of flying debris |

Anti-Vibration Design |

Minimizes machine movement | Improves precision, reduces fatigue |

Overload Protection |

Shuts down if overloaded | Prevents motor damage |

Always prioritize machines with robust safety features to ensure accident-free operation.