Title

In the world of precision manufacturing, gears are fundamental components found in everything from automotive transmissions to industrial robotics. Yet, despite the critical role they play, one essential finishing process is often underestimated — gear chamfering.

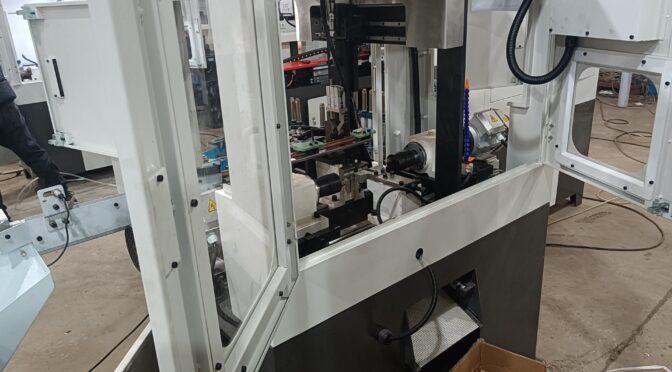

Investing in a dedicated gear chamfering machine can have a significant impact on production quality, efficiency, and overall equipment performance. This article explains why gear chamfering matters, and why it’s worth investing in specialized machinery for the task.

- What Is Gear Chamfering?

Gear chamfering is the process of removing the sharp edges or burrs from the ends of gear teeth. This is typically done on the face and root ends of the gear profile, ensuring smoother handling, easier assembly, and reduced wear during operation.

While it may seem like a minor detail, chamfering is crucial in applications where gears engage at high speeds, under load, or in environments where noise, vibration, and durability are concerns.

- Why Is Gear Chamfering Important?

Chamfering gears offers several key benefits:

Improved Meshing: Chamfered edges promote smoother engagement between gear teeth, reducing backlash and transmission noise.

Deburring for Safety: Sharp edges and burrs can pose a safety risk during handling and assembly. Chamfering removes these hazards.

Reduced Tooth Breakage: Unchamfered gear teeth are more susceptible to edge chipping and fatigue cracks, especially under repeated stress.

Better Lubrication Flow: Chamfered edges allow better oil flow between gear teeth, enhancing cooling and wear resistance.

- Manual vs. Automated Chamfering

While some manufacturers still rely on manual deburring and edge rounding, this approach has clear limitations:

Inconsistency: Manual processes vary from operator to operator, resulting in inconsistent gear quality.

Time-Consuming: Manual chamfering slows down production cycles and increases labor costs.

Higher Rejection Rates: Without precision, gears may not meet tolerances and require rework.

By contrast, a gear chamfering machine offers:

Consistent and repeatable results

Faster cycle times

Precision control over chamfer size and angle

Integration into automated gear production lines

- Benefits of Investing in a Gear Chamfering Machine

Here’s why a dedicated chamfering machine is a smart investment:

Improves Overall Gear Quality: Chamfers are uniform and precisely controlled, enhancing reliability and lifespan.

Reduces Rework and Scrap: Automation ensures higher pass rates and fewer dimensional errors.

Increases Production Speed: Chamfering is completed quickly and in sync with your machining or hobbing process.

Enhances Product Appearance: Clean, consistent chamfers give gears a professional finish — critical for high-end or visible components.

Boosts Downstream Performance: Chamfered gears cause less wear to mating components, leading to better performance in the final assembly.

- Industries That Benefit from Gear Chamfering Machines

Automotive: Transmissions, differential gears, and steering systems

Aerospace: Actuators, gearboxes, turbine control systems

Industrial Automation: Robotics, reducers, machine tool drives

Heavy Machinery: Construction and mining equipment gear systems

Precision Instrumentation: Small-scale high-accuracy gear assemblies

Conclusion

Gear chamfering is not just a finishing touch — it’s a critical quality step that directly affects performance, reliability, and customer satisfaction. Investing in a gear chamfering machine brings precision, speed, and consistency to this essential process, making it a valuable addition to any gear production line.

In a competitive manufacturing environment, the smallest detail can define the biggest difference — and in gear production, that detail may just be the chamfer.