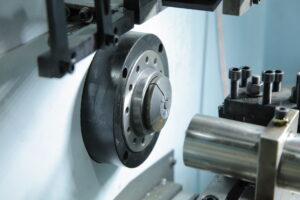

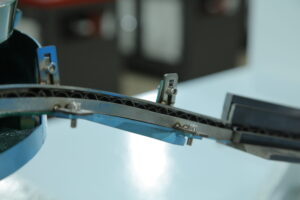

In the field of precision manufacturing, machining small components often presents two major challenges: limited space and complex processes. Traditional large-scale machine tools are not flexible enough to accommodate miniature workpieces, while multi-process operations require frequent machine changes, resulting in inefficiency. CNC Miniature Machine Tools overcome these obstacles with their compact design, multi-functional integration, and high-precision control, setting a new standard for small parts machining. These machines offer a one-stop solution for industries such as electronics, medical devices, and watches.