Crimping is a style of joining wires to metal fittings that are then used to connect the wire to another wiring component or to other wires.

The fittings themselves come in various styles, and are collectively known as “crimp connectors.”

They are most commonly used with stranded wires found in the wiring of appliances, electronics, or automobile systems.

The technique involves compressing a small insulated metal sleeve on the end of the connector around the exposed bare wires.

Wire connections using crimp connectors are often used in locations where the heat of soldering is not appropriate, or where the wire connection may need to be detached occasionally.

Connections made with crimp connectors take up little space; they also are easier to make than solder connections and when done properly, they can be just as effective.

When you crimp a connector onto the end of a wire, the idea is to form a tight, continuous electrical union between the wire and the connector fitting that will stay together permanently.

To achieve this, both the connector sleeve and the wire both have to be malleable enough to deform under a compressive force.

An electrical connector is a device for joining electrical circuits together using a mechanical assembly.

The connection may be temporary or serve as a permanent electrical joint between two wires.

There are hundreds of types of electrical connectors.

Connectors may join two lengths of wire together or connect a wire to an electrical terminal.

Crimp connectors work best with stranded wire because solid wire usually isn’t malleable or ductile enough to make a reliable connection.

The wire gauge isn’t a major factor.

You can crimp a connector onto beefy 8-gauge wire as effectively as you can onto 18-gauge wire, as long as you use a connector of the right size.

Below area few connector types.

On the far, upper left, we have an insulated splice connector to connect two wire ends together.

To the right, the forked connector (spade, or split ring) is useful for connecting wire to screw terminals by sliding the fork into a screw terminals’s socket.

Screws can be partially screwed in before installing the terminal.

The ring terminals in the middle are also useful for connecting wire to screw terminals.

While the ring terminal provides a more reliable connection, you would need to completely remove the screw before installing the terminal.

On the far, upper right we have a male spade connector (blade).

These can slide into the female spade connector (double crimp) that is shown on the bottom right.

Depending on the design and application, these connectors can come in different flavors like flanged fork or locking ring terminal.

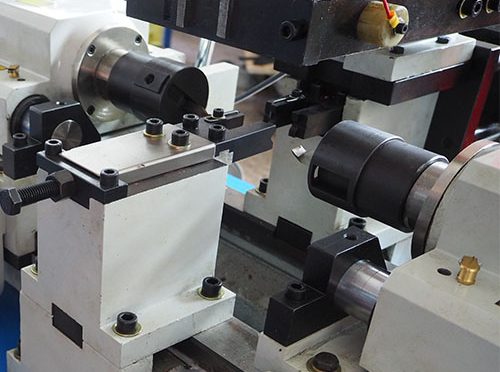

To achieve the necessary compressive force, it’s best to use a crimping tool when attaching crimp connectors to a wire.

Pliers or a hammer will work in a pinch, but using such tools can result in a loose connection that ultimately results in an open circuit.

Nothing is more difficult to diagnose than a loose crimp connection in complex automotive and appliance electrical systems, where crimping is most commonly used.

Choose the Right Connector

Crimp connectors come in many styles, so make sure you choose the right one for the application.

- A ring connector makes the most secure connection to a terminal post. It can be disconnected only if nut on the terminal is removed.

- A spade connector is best for situations in which it’s impractical to remove the nut from the connection terminal. The spade-shaped tip slides into a socket on the terminal.

- A quick-disconnect connector can be barrel-shaped or blade-shaped. You can separate the connection by pulling the two halves apart.

- A butt connector permanently splices two wires together.