Title

Leading paragraph:

Servo motors have become indispensable in modern manufacturing and automation. Their ability to deliver precise control and high performance makes them a cornerstone of advanced technologies across various industries.

Featured paragraph:

Servo motors offer high precision, dynamic response, and reliability, making them ideal for applications ranging from industrial automation to medical devices. As technology advances, servo motors are becoming smarter, greener, and more integrated into cutting-edge systems.

Transition paragraph:

Let’s explore the fundamentals of servo motors, their applications, advantages, and future trends that are shaping the industry.

I. Basic Concepts of Servo Motors

Leading paragraph:

Understanding the basics of servo motors is crucial for appreciating their role in modern technology. These motors are designed for precision and reliability.

Featured paragraph:

Servo motors are designed to provide precise control over speed and position. They consist of a motor, reducer, encoder, and controller, and are classified into DC and AC types.

Dive deeper paragraph:

Definition and Characteristics: Servo motors are specialized motors that can accurately control rotational speed and position. They are known for their high precision, dynamic response, stability, and reliability, making them suitable for applications where exact control is essential.

Components and Classification: A typical servo motor system includes a motor, reducer, encoder, and controller. These components work together to achieve precise motion control. Servo motors are broadly categorized into DC and AC types, with AC servo motors being more common in modern applications due to their superior performance and efficiency.

II. Working Principle of Servo Motors

Leading paragraph:

The operation of servo motors relies on a sophisticated control system that ensures precise movement.

Featured paragraph:

Servo motors operate through a control loop system involving command input, control, output, and feedback. This feedback mechanism enables high-precision and responsive operation.

Dive deeper paragraph:

Control Loop: The control loop is the backbone of servo motor operation. It consists of four key steps: command input, control processing, output to the motor, and feedback. The feedback loop continuously monitors the motor’s position and speed, comparing it to the desired values and making adjustments in real-time.

Feedback Mechanism: The feedback mechanism, typically provided by an encoder, is crucial for achieving high precision and responsiveness. It allows the motor to correct any deviations immediately, ensuring accurate and reliable operation.

III. Applications of Servo Motors

Leading paragraph:

Servo motors are ubiquitous in modern industries, driving efficiency and precision in various applications.

Featured paragraph:

Servo motors are used in industrial automation, CNC machines, medical devices, aerospace, logistics, and smart homes, providing precise control and high performance.

Dive deeper paragraph:

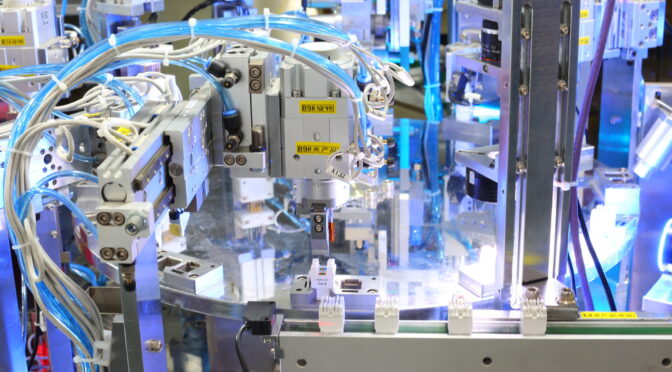

Industrial Automation: Servo motors are integral to automated production lines and robotic systems, enabling high-speed, efficient, and precise operations. They ensure consistent product quality and increased productivity.

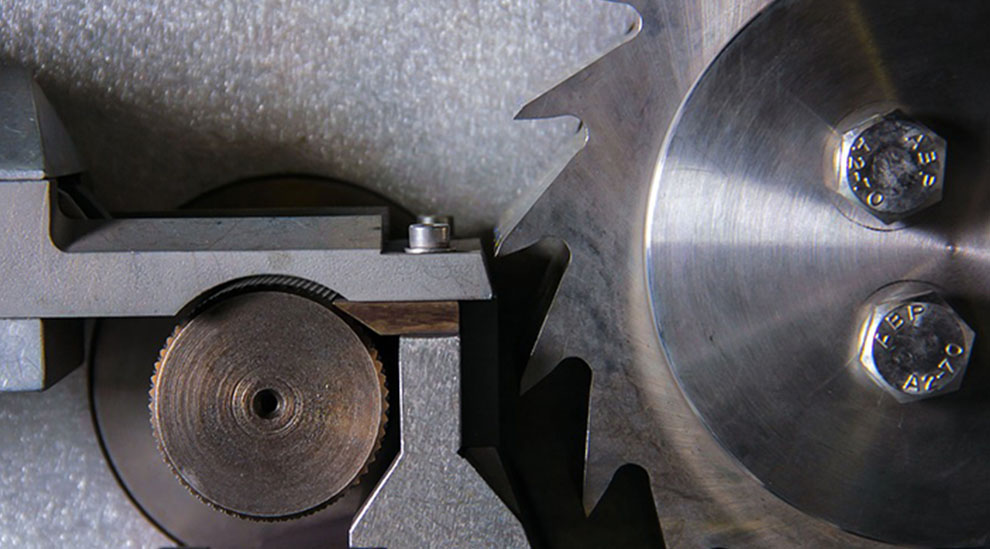

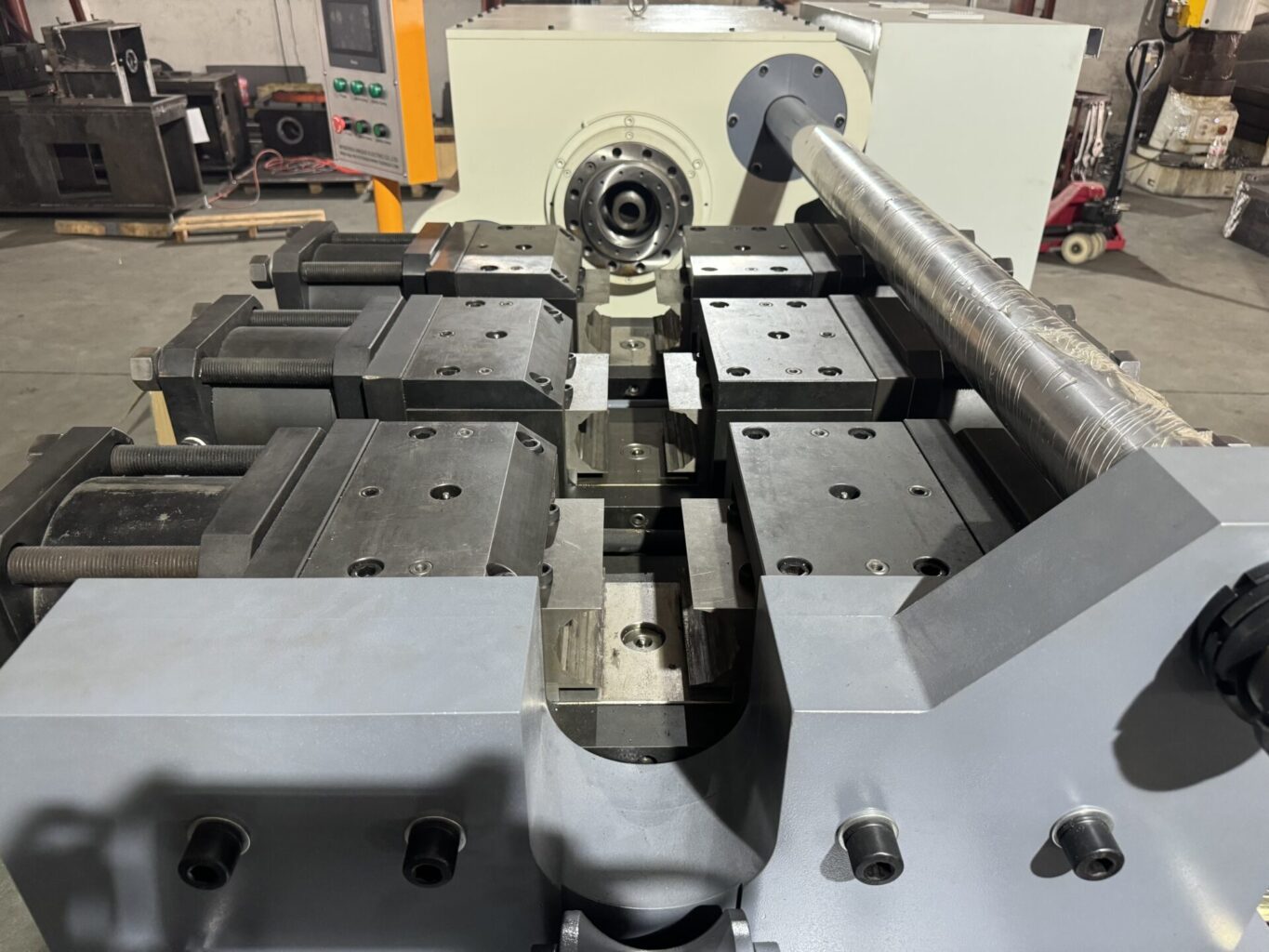

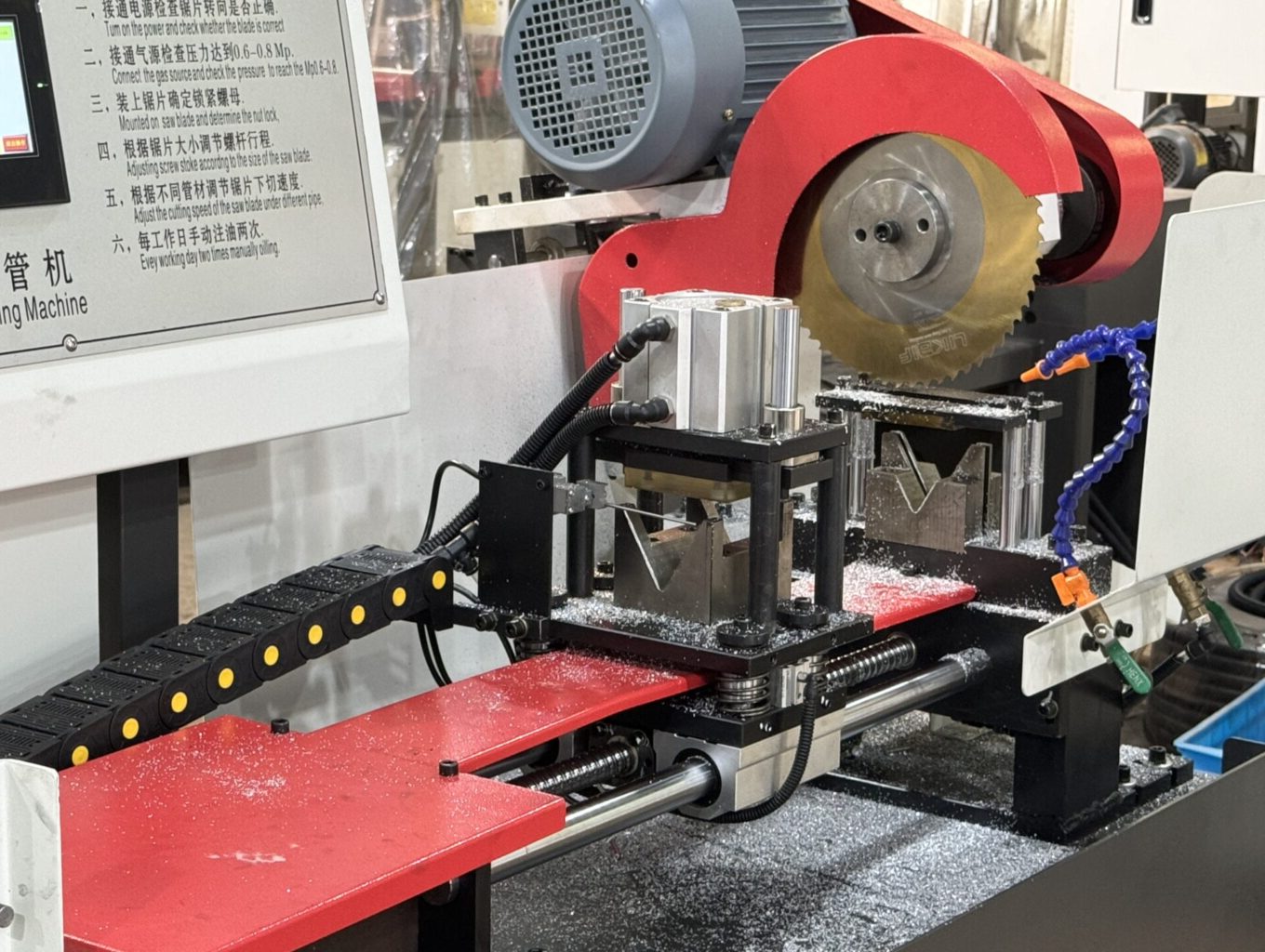

CNC Machines: In CNC machines, servo motors drive the various axes, achieving precise cutting and machining. Their high precision and reliability are critical for manufacturing high-quality components.

Medical Devices: In medical applications such as surgical robots and CT scanners, servo motors provide precise speed and position control, ensuring accurate and safe operation.

Aerospace: Servo motors are used to control the attitude and position of aircraft, enabling precise navigation and positioning. Their reliability and precision are crucial in this high-stakes industry.

Logistics: In logistics, servo motors power automated sorting, warehousing, and conveying systems, enhancing efficiency and accuracy in material handling.

Smart Homes: Servo motors can be found in smart home applications like window and curtain control, adding a layer of automation and convenience to modern living.

IV. Advantages of Servo Motors

Leading paragraph:

The benefits of servo motors are clear, making them a preferred choice for precision applications.

Featured paragraph:

Servo motors offer high precision, fast dynamic response, and stable performance across various operating conditions.

Dive deeper paragraph:

High Precision: Servo motors can achieve very high levels of position and speed control accuracy, making them suitable for applications requiring exact motion.

Fast Dynamic Response: They can quickly respond to control commands, adapting to rapidly changing demands and ensuring smooth operation.

Stability: Servo motors maintain stable performance in diverse environments, ensuring consistent operation and reliability.

V. Future Development of Servo Motors

Leading paragraph:

As technology advances, servo motors are evolving to meet new challenges and opportunities.

Featured paragraph:

The future of servo motors lies in intelligence and automation, green manufacturing, and technological innovation and cooperation. These trends will drive continuous improvement and integration into advanced systems.

Dive deeper paragraph:

Intelligent and Automated Systems: Future servo motors will integrate more intelligent features, such as fault diagnosis and remote monitoring, enhancing their autonomy and efficiency.

Green Manufacturing: Emphasis on environmental sustainability will drive the adoption of energy-efficient and eco-friendly technologies in servo motor design and operation.

Technological Innovation and Collaboration: Collaboration with research institutions and universities will fuel continuous technological innovation, leading to the development of more advanced servo motor solutions.

Conclusion

Servo motors are a vital component in modern manufacturing and automation, offering precision, reliability, and adaptability. As technology progresses, these motors will become smarter, greener, and more integrated into advanced systems, driving continuous improvement and innovation across industries.